The Solution

Customised air-moving solutions are what AirEng prides itself in, so it is no surprise that our local team of dedicated designers, engineers and skilled production staff are able to supply Gordon Brothers with industrial fans that are not only efficient over time in terms of power but achieve each of their own individual goals.

A recent project across three mining sites in Fosterville, Victoria, Tanami Mine, Northern Territory and Dugald River, Queensland saw multiple budget requirements and different applications.

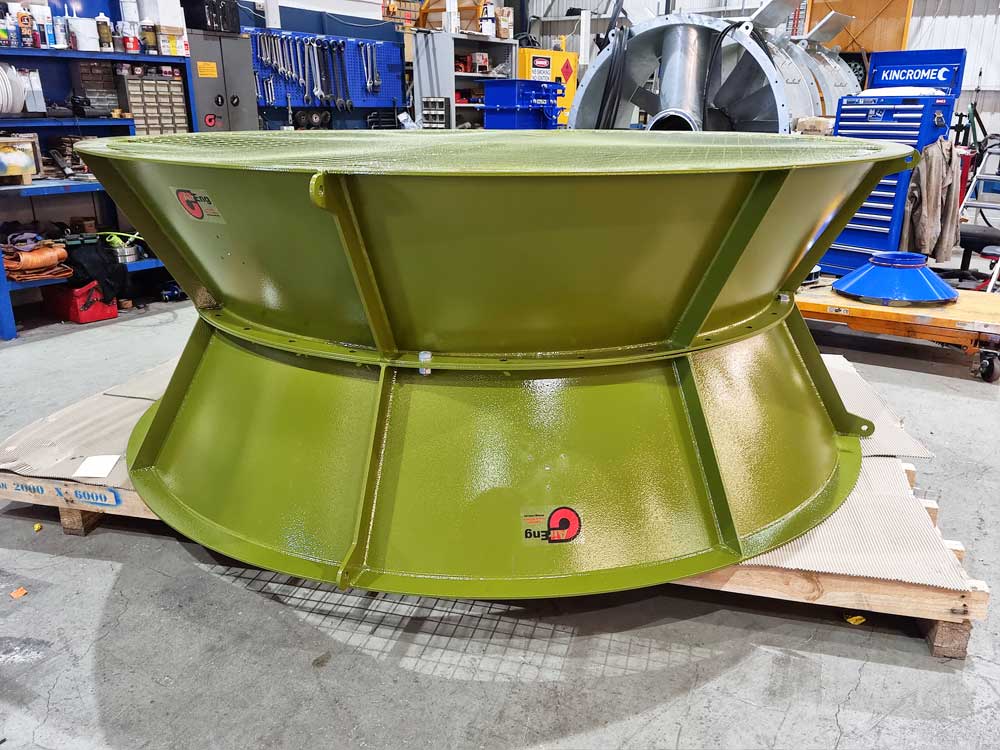

The Fosterville and Tanami fans required low noise-output. Given Gordon Brothers’ overarching brief of long-term efficiency, AirEng worked to design a fan that achieved low noise-output but was also efficient. The outcome was a fan with Low Pressure High Efficiency (LPHE) blades, no silencer, a unique guide vane arrangement inside the casing along with a machined and fabricated hub, making it a much higher performing fan.

This was a hugely successful, and rewarding, project as the assembly required a completely new design, extensive engineering from the AirEng team, along with significant collaboration with Gordon Brothers to ensure the best outcome.

AirEng designed the blades for the Fosterville and Tanami Axial fans from scratch, using legacy data from parent company NYB. This involved Finite Element Analysis (FEA) and flutter analysis of the impeller, along with 3D print modelling for aluminium casting.

The LPHE blades featured an adjustable pitch angle, allowing for different flow-pressure-power consumption making the fans extremely versatile for use across a variety of applications.

The arrangement of the fan base was also a completely new design as the fans were to sit in a vertical position on heavy bases which sit on a drift. This required further FEA for the casing, natural frequency vibration analysis for the base frame and Computational Flow Modelling (CFD) analysis the drift. This CFD analysis was a worthwhile exercise as it allowed AirEng and Gordon Brothers to come to a final recommendation which would minimise pressure losses, ensuring the highest efficiency fan for the client.

For the Dugald River project, noise wasn’t a concerning factor so AirEng were able to supply a more cost-effective solution, that still achieved long-term cost efficiency. The Axial fans featured a tightened impeller (supplied by Titan) and high specification TECO motor.