High tech for an intelligent wastewater treatment

Special Applications

Special Applications

Water is one of the most precious treasures of this planet. And clean water is the most important resource making life possible on earth. However, the explosive increase of the world population, the enormous development of mega-cities as well as the rapid progressing of industrialisation augment the worldwide need for clean water. In Germany alone, the production site of PillAerator, more than 10,000 wastewater treatment plants clean approximately 10 billion m³. The plants are fed by a sewage network of 515,000 km (that’s 13 times around the globe). Each year thousands of smaller and larger plants are added which shows the importance of purification quality.

Protecting the environment means saving energy and conserving precious resources. That’s why we at PillAerator GmbH have rolled up our sleeves and developed the PillAerator. The innovative turbo compressor is a real multi-talent and has an important share in improving the water quality and operates so efficiently that the operation costs of the plant decrease.

For this development, the PillAerator has received an innovation award in which the PillAerator stood up to more than 2,000 applicants. The award honors the efforts for a highly-efficient product which combines state-of-the-art components. The innovative development is not only present in a smooth and energy-efficient running performance but also in a nearly maintenance-free design.

It keeps going. And going. And going. As the impeller and the high-performance synchronic-motor are directly connected and the rotor unit floats contact-free in a magnetic field, wear-intensive components are omitted. Nevertheless, the motor is absolutely gas-tight and cannot be polluted by the ambient air. This increases the performance safety, the on line availability and life-time of the machine.

Beyond Borders. The frequency converter enables the compressor to run at the exact operation point. Mechanical regulating devices which can wear or allow only restricted positions at reduced efficiency are not necessary. The excellent efficiency of the frequency converter supports also the energy efficiency of the PillAerator. State-of-the-art measuring, innovative design and a perfect composition of the main components allow a operation between 15 % and 100 % with an efficiency of up to 88 %.

The Communicative Type

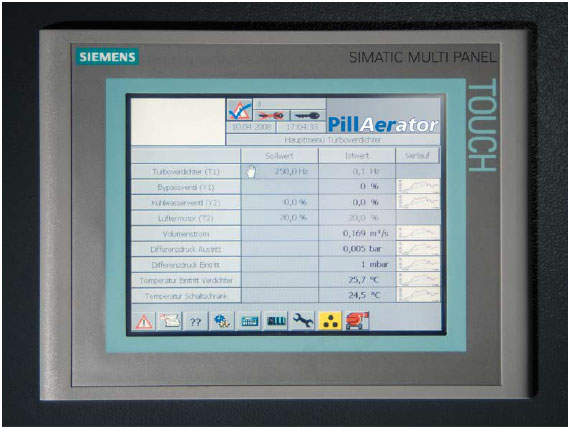

The S7-300 control with its touch-screen panel allows the operators to quickly view all operating conditions of the PillAerator. All operating modes like pressure and volume flow control or an external set point/actual value control such as a D.O. signal are standard options. Via this Human-Machine-Interface all operating parameters can be monitored and modified. The easy to understand symbols makes the handling self-explanatory. Moreover, the control is also equipped with the destination’s national language. Via Profibus DP the PillAerator can be connected with the master control room of the plant. Upon request our Service-Department at our headquarters will monitor your machine within the scope of service-agreement via a cordless GPRS/UMTS connection. Technical enhancement and changes within the plant can be considered even after years of operation.

Silence, please!

An integrated intake silencer and a soundproof cabinet keep the sound emission below 80 dB(A). Additional sound protection is not necessary.

Stays cool even if it’s hot

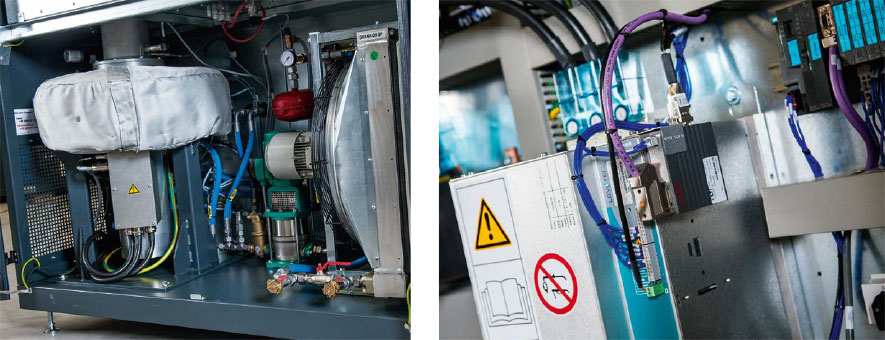

The cooling system of the PillAerator insures that the machine always operates at a proper temperature. The combination of air-water and water-water cooling dissipates the process heat and guarantees stable temperature conditions which supports the lifetime of the motor, the electronic components and the performance of the PillAerator even at high temperatures.

No more compromises

Perfection is not reached when there is nothing more to add but when there is nothing more that can be left out. We have designed the PillAerator according to this motto. No accessories, no extras because everything, from the intake filter to the electronics of the magnetic bearing, is included in the PillAerator right from the beginning. The compact design allows a quick and easy installation with a maximum of quality and is 100 % oil-free.

Which maintenance?

The PillAerator has an integrated intake filter. Via a differential pressure measuring the degree of pollution is monitored and the filter must be changed one to two times a year accordingly. That is so easy that it can be done by the customer as it saves time and money. More maintenance is not necessary for the PillAerator.

Power break down!

Well Then? A safe permanent power supply is not available everywhere. To avoid damage of the magnetic bearing in case of a power failure, the PillAerator Team has developed a solution which does not need additional and maintenance-intensive components like batteries or ups units. After a power failure the PillAerator is immediately ready of operation without any additional measures.

(Click to enlarge graphic)

This example shows a fabricated stainless steel MPD type impeller. This fan was used as a HVAC application on an off-shore platform.

To come